Keep Employees and Premises Safe

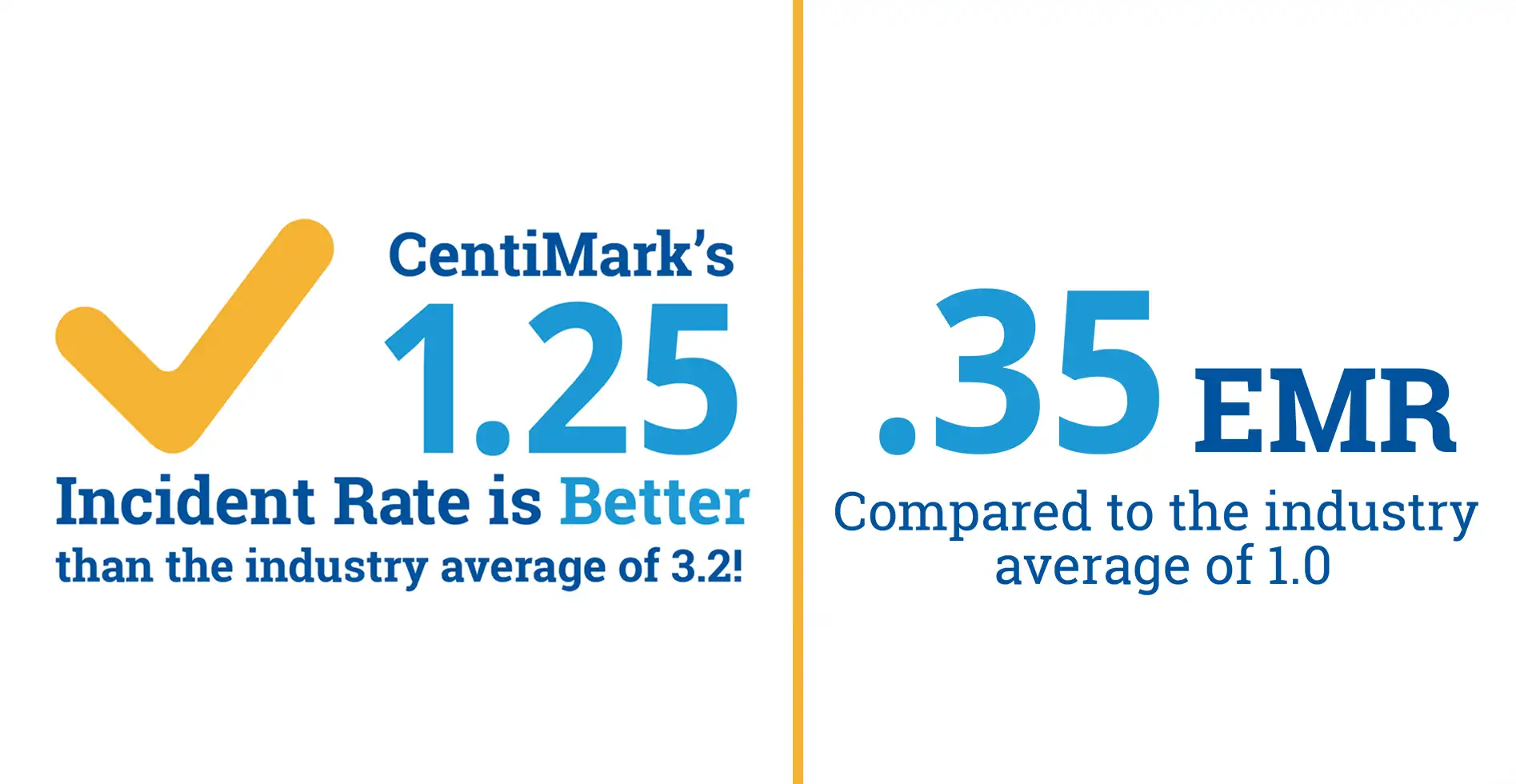

Working at heights comes with risks and we go above and beyond to protect everyone on the roof and below. Our proactive approach allows us to address safety challenges head-on and cultivate a culture of vigilance and responsibility.